|

Schiller Institute Conference Tom Ferreira |

Tom Ferreira is Senior Manager of Corporate Communications for Pebble Bed Modular Reactor (Pty) Ltd. of the Republic of South Africa. This paper was prepared for the Schiller Institute's conference in Kiedrich, Germany, September 15-16, 2007.

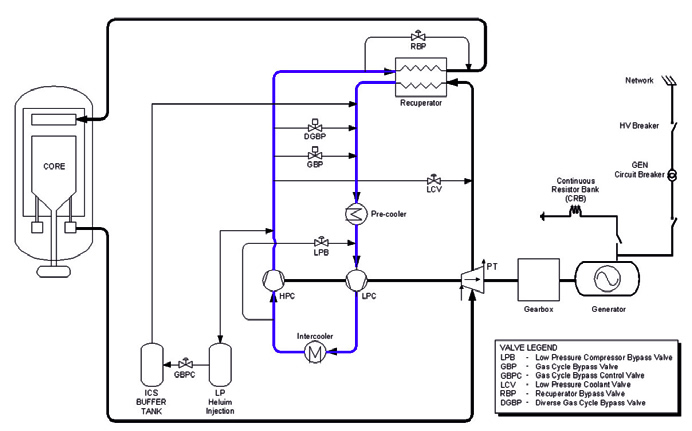

| FIGURE 1 Schematic of a Process Heat Plant  |

| PBMR, Ltd. |

|

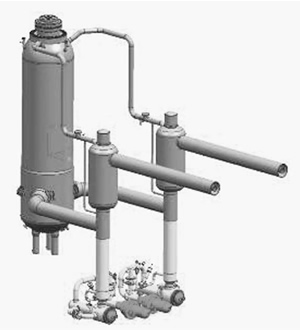

| PBMR, Ltd. Koeberg near Cape Town, South Africa: the site earmarked for the first commercial scale pebble bed modular reactor. |

Safe, clean, cost-competitive, versatile, and adaptable. These, in a nutshell, are the features of the Pebble Bed Modular Reactor (PBMR).

Locally, the PBMR technology has the potential to provide South Africa with competitive power generation in coastal areas. Internationally, it will be competitive with virtually all other forms of energy generation.

Most of South Africa's coal-fired electricity is generated by large-scale plants built near the pit-heads of two extensive coal-producing areas, both of them far inland on the eastern side of the country. This requires long power lines from the coal-rich areas to load centers away from the pit-heads, which in turn implies high capital costs and transmission losses.

New power stations have to be built to ensure that the country's capacity keeps up with demand. In addition, the country's older power stations reach the end of their design life after 2025. South Africa will, therefore, need to access and use all natural resources to produce the additional 40,000 MW of electricity that will be needed over the next 20 years (over and above the currently installed 39,000 MW).

A typical coal-fired power station requires a construction lead time of about eight years, and could result in the installation of surplus capacity if economic growth is not as expected. Shorter lead times would enable power utilities to drastically shorten their decision-making horizon for the addition of new capacity, and to add capacity in smaller increments.

The South African electricity utility Eskom, like most utilities worldwide, also experiences short, sharp demand peaks in Winter that are difficult to accommodate with the slow ramping characteristics of the existing large power stations.

These factors prompted Eskom to investigate small electricity generation plants that can be placed near to the points of demand. The PBMR concept, which has a 24-month construction time (from first concrete to fuel load), low operating cost, and fast load-following characteristics, is such an option. While open-cycle gas turbines, coal-fired plants, and conventional nuclear reactors are all good options in the short and medium term, the PBMR could play a crucial role to help meet the country's energy requirements from the second half of the next decade onwards. Its inherent safe characteristics and positive attributes from an environmental point of view, add immensely to the attractiveness of this technology.

It is therefore envisaged that at least 20% of Eskom's new nuclear build program of 20,000 MW will consist of PBMRs (between 24 and 30 modules generating 165 MW each).

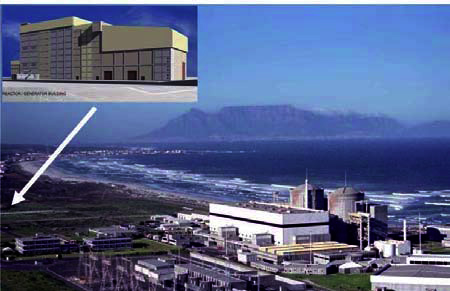

FIGURE 2  |

| PBMR, Ltd. The PBMR modules are sized to produce 165 MWe. To maximize the sharing of support systems, however, the PBMR has been configured into a variety of options, such as a four-pack layout. This is the most cost-effective layout, and allows the plants to be brought on line as they are completed. |

Project Status

Since its establishment in 1999, Pebble Bed Modular Reactor (Pty) Ltd has grown into the largest nuclear reactor design team in the world. In addition to the core team of some 700 people at the PBMR head-office in Centurion near Pretoria, more than a thousand people at universities, private companies, and research institutes are involved with the project. Around the world, scientists and governments are looking to South Africa with great interest to see how the local nuclear reactor developments unfold.

The PBMR team is currently preparing for the building of a commercial-scale power reactor project at Koeberg, near Cape Town, where Africa's only nuclear power station is based, and a fuel plant at Pelindaba near Pretoria. The current schedule is to start construction in 2009 and for the first fuel to be loaded four years later. Construction of the first commercial PBMR modules is planned to start three years after the first fuel has been loaded into the demonstration reactor.

Investors

PBMR's current investors, the South African government, the South African electricity utility Eskom, the Industrial Development Corporation of South Africa, and the American nuclear giant Westinghouse, share the vision of small, standardized, inherently safe, modular reactors as one of the best carbon-free alternatives for new power-generation capacity around the world.

Westinghouse's decision to become a shareholder in PBMR, is a clear indication of the confidence in the pebble bed technology's technical, commercial, and export potential. The PBMR project also enjoys solid support from the South African government, which regards it as one of the most important capital investment and development projects yet undertaken in the country.

Process Heat Applications

While PBMR's research and development efforts were initially focused mainly on electricity generation, it has become increasingly apparent that the high-temperature, gas-cooled reactor technology will also enable access to markets that call for process heat applications. Next-generation high-temperature reactors such as the PBMR can produce hydrogen for transportation or for upgrading coal and heavy crude oils into usable products, thereby relieving pressure on natural gas supply (the source of most hydrogen produced today). They can also generate process heat for desalination, to extract oil from tar sands, and for many other industrial applications.

Capable through its very high temperatures of 900°C, the PBMR technology is ideally placed for these applications.

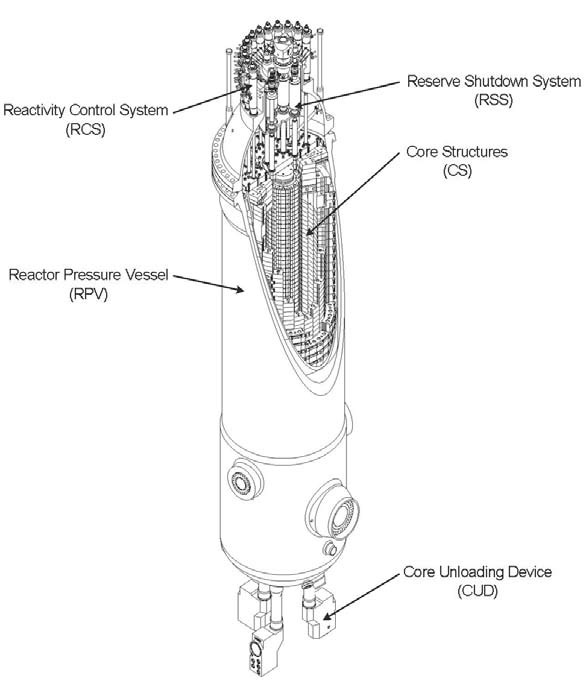

| FIGURE 3 PBMR Schematic  |

| PBMR, Ltd. |

To this end, the South African synthetic fuels company Sasol is in discussion with PBMR to explore the possibility of replacing its coal-fired boilers with reactors. Sasol has also had preliminary discussions with the government about the potential for PBMR technology and how it can be used in the synfuels industry. It is not inconceivable that such a nuclear heat supply system could be operating by 2015.

In Canada, there is interest from companies involved in the oil sands business, to use the high temperatures created in PBMRs to create extremely super-heated steam to extract bitumen from oil sands, instead of gas-fired plants currently in use.

PBMR is also a partner in a concept design contract with the U.S. Department of Energy, to consider the PBMR technology as a future source of hydrogen. The project is still in its pre-conceptual phase, but it could result in the construction of a South African-designed Pebble Bed Modular Reactor in the U.S. before the end of the next decade.

The PBMR technology, furthermore, has desalination properties. To this end, the Department of Water Affairs has requested PBMR to work on a proposal for utilizing the waste heat of the demonstration reactor at Koeberg for desalination purposes.

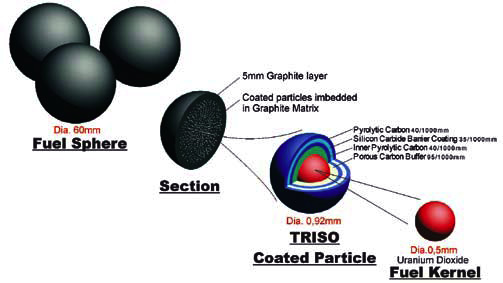

| FIGURE 4 Fuel Spheres  |

| PBMR, Ltd.. |

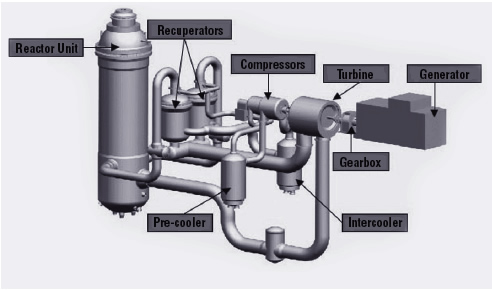

| FIGURE 5 Schematic of the Power Conversion Unit  |

| PBMR, Ltd.. |

Small Size

The PBMR is based on the philosophy that the new generation of nuclear reactors should be small. Each module would be sized to produce 400 MWt (165 MWe nominal), which is about 18% of the output of conventional reactors such as the ones at Koeberg near Cape Town.

The main building and generator of a module will cover an area of about 4,320 m2 (108 m × 40 m), which means that two modules would fit on a soccer field. The height of the building will be 66 m, more than a third (23 m) of which will be below ground level.

The PBMR is being designed in a modular fashion to allow for additional modules in accordance with demand. Dry cooling, although more expensive, is an option that would provide even more freedom of location. In addition, the PBMR can be used both as a base-load or load-following station, and can be configured to the size required by the community it serves. The technology is also well suited for hydrogen production, district heating, and desalination purposes.

Safety Features

The PBMR has a simple design basis, with inherent safety features that require no human intervention, and which cannot be bypassed or rendered ineffective in any way.

If a fault occurs during reactor operations, the system, at worst, will shut down and merely dissipate heat on a decreasing curve, without any core failure or release of radioactivity to the environment.

The helium, which is used to transfer heat from the core to the power-generating gas turbines, is chemically inert. It cannot combine with other chemicals or elements and is non-combustible.

The inherently safe design characteristics of the PBMR render obsolete the need for safety backup systems and most aspects of the off-site emergency plans required for conventional nuclear reactors. It is also fundamental to the cost reduction achieved over other nuclear designs. Although plans related to aspects such as the transport of fuel will still be required, they will be modified to suit the specific characteristics of the fuel and the transport mode.

The reactor core concept is based on the well-tried and proven German AVR power plant, which ran for 21 years. This safe design was proven during a public and filmed plant safety test, when the flow of coolant through the reactor core was stopped and the control rods were left withdrawn just as if the plant were in normal power generation mode.

It was demonstrated that the reactor core shut itself down inherently within a few minutes. It was subsequently proven that there was no deterioration over and above the normal design failure fraction of the nuclear fuel. This proved that a reactor core meltdown was not credible, and that an inherently safe nuclear reactor design had been achieved.

| FIGURE 6 The PBMR Power Conversion Unit  |

| PBMR, Ltd.. |

Spent Fuel Management

A 165 MWe PBMR module will generate about 32 tons of spent fuel pebbles per annum, about one ton of which is uranium. The storage of PBMR spent fuel is much easier than for fuel elements or rods from conventional nuclear reactors, as no safety graded cooling systems are needed to prevent fuel failure.

The PBMR system has been designed to deal with nuclear waste efficiently and safely. There will be enough room for the spent fuel to be stored in dry storage tanks at the PBMR plant for the power station's expected 40-year operational life, during which time no spent fuel will have to be removed from the site. After the plant has been shut down, the spent fuel can be safely stored on site for another 40 years before being sent to a final repository.

How the PBMR Works

The PBMR is a helium-cooled, graphite-moderated, High-Temperature Reactor (HTR). It has a 27 m (88 ft) high vertical steel Reactor Pressure Vessel (RPV) with an inner diameter of about 6.2 m (20 ft). The RPV contains and supports a metallic core barrel. The core barrel, in turn, supports the annular pebble fuel core, which is located in the space between a central and outer graphite reflector. Vertical borings in these reflectors are provided for the reactivity control elements.

Two diverse reactivity control systems are provided for shutting the reactor down. One of the systems is 24 control rods in the outer reflector, while the other consists of small absorber spheres which are dropped into eight borings in the central reflector.

The PBMR uses particles of enriched uranium dioxide coated with silicon carbide and pyrolytic carbon. The particles are encased in graphite to form a fuel sphere or pebble about the size of a billiard ball. Helium is used as the coolant and energy transfer medium, to drive a closed cycle gas turbine-compressor and generator system. When fully loaded, the core would contain approximately 450,000 fuel spheres.

To remove the heat generated by the nuclear fission reaction, helium coolant enters the reactor vessel at a temperature of about 500°C (932°F) and a pressure of 9 MPa or 1,323 pounds per square inch (psi). The gas flows down between the hot fuel spheres, after which it leaves the bottom of the vessel having been heated to a temperature of about 900°C (1,652°F).

The hot gas then enters the turbine, which is mechanically connected to the generator through a speed-reduction gearbox on one side and the gas compressors on the other side. The coolant leaves the turbine at about 500°C (932°F) and 2.6 MPa (377 psi), after which it is cooled, recompressed, reheated, and returned to the reactor vessel.

The thermodynamic cycle used is a Brayton cycle with a water-cooled pre-cooler and intercooler. A high-efficiency recuperator is used after the power turbine. The helium, cooled in the recuperator, is passed through the pre-cooler, low-pressure compressor, the intercooler and high-pressure compressor, before being returned through the recuperator to the reactor core.

The power taken up by the helium in the core and the power given off in the power turbine is proportional to the helium mass flow rate for the same temperatures in the system. The mass flow rate depends on the pressure, so the power can be adjusted by changing the pressure in the system.

The high-pressure and high-temperature operation of the reactor results in a relatively high thermal efficiency. While a typical light-water reactor has a thermal efficiency (electrical power output/thermal heat input) of approximately 33%, an efficiency of about 41% is anticipated in the basic PBMR design.

Online refuelling is another key feature of the PBMR. Fresh fuel elements are added to the top of the reactor, while used fuel is removed at the bottom while the reactor is at power.

The aim is to operate uninterrupted for six years before the reactor is shut down for scheduled maintenance. However, for the demonstration module, a number of interim shutdowns will be required for planned evaluation of component and system performance.

Shutdown will be done by inserting the control rods. Start-up is effected by making the reactor critical, then using nuclear heat-up of the core and circulating the coolant by motoring the turbo-generator set. Heat is then removed by the pre-cooler and intercooler. At a specified temperature, the cycle becomes self-sustaining.

Related pages:

More Speeches from the Schiller Institute Landbridge Conference

Strategic Studies

New Technologies and the Global Challenges for Civilization

Water from the Gulf of Mexico Can Green the Great American Desert

A Nuclear-Powered Desalination Plant for Use in the Middle East

MAPS of Great Infrastructure Development Projects Around the World